| Update : may 19th, 2018 |

VCO

|

|

back to summary |

|

|

| Description |

| Update : may 19th, 2018 |

VCO

|

|

back to summary |

|

|

| Description |

|

|

|

Schematics |

|

|

|

|

Components and building details |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

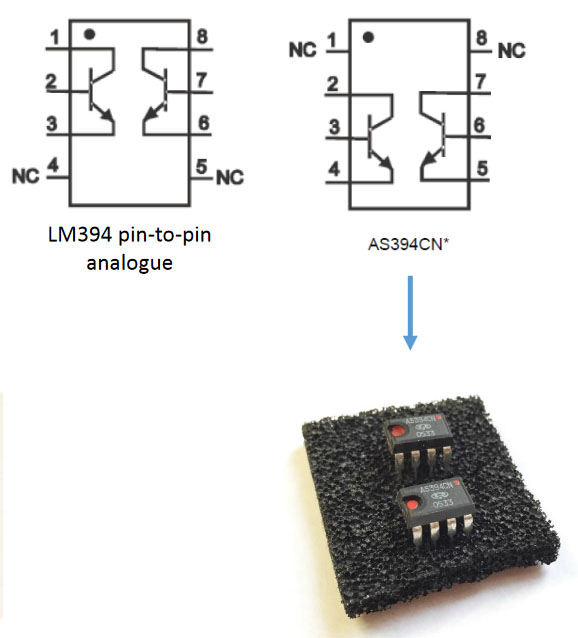

| IMPORTANT NOTE : for C8 use a

high grade low temperature drift capacitor

(styroflex or silver mica) If you choose to use a SSM2210 instead of a LM394, the value of R15 (10K) must be increased to 100K. NOTE CONCERNING THE AS394 : some people using AS394 as a replacement for the LM394 had difficulties with the pinout becaus of an ambiguous marking AS394 : Famous LM394 matched

transistors analogue made in Latvia. NB!

transistor configuration is the same, but pins are

shifted up but futhermore there are ambiguous red

spot on the IC. When using these on the

YuSynth VCO PCB which is designed for standard

LM394 pinout, you need to cut pins 1 and 8 off,

and shift the IC up in the socket- pinout below

explains it all - well we thought it did but Bob B

asked for clarification as to which is pin 1 as it

is confusing with those red blobs. We agree so

armed with a meter on the diode range revealed

that the small red dot is next to pin 5. The notch

in the case is at the top of the chip.  ` |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal coupling Thermal

coupling between the tempco resistor and the

transistor pair of the exponential converter

is an important condition for insuring a

good stability of the VCO. The following

pictures show how to install these critical

components on the PCB.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Proposed modification of the tempco section Mariano from Dallas,

Texas has moded the VCO in order to use an easy to

source NTC resistor as a replacement for the PTC

tempco resistor. This mod is described as well as

other mods in a PDF file located at the end of

this page in the Gallery section.

Thanks Mariano !

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

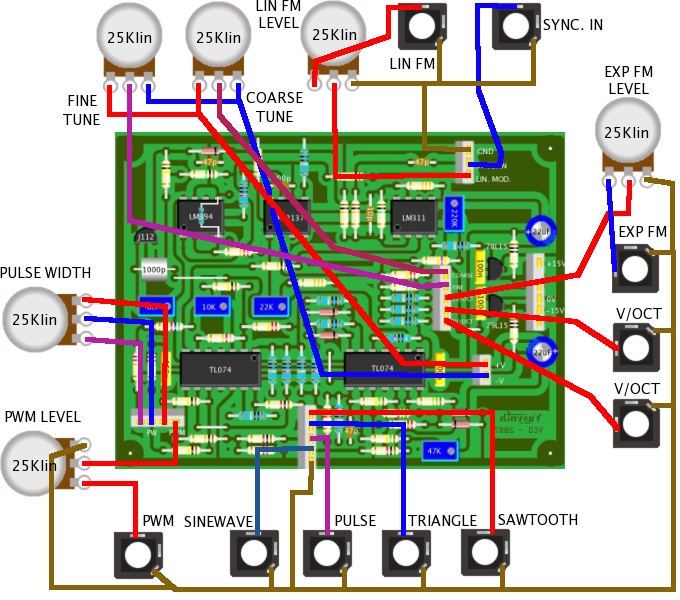

| Wiring Wiring option : the

SYNC IN jack may be either connected to the

HARD SYNCH or the SOFT SYNCH connector

depending on your taste. You may even add a

switch on the front panel in order to select

between the two hard synch modes.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

Setting and trimming

|

|

For setting and

trimming of the VCO, you need a good Oscilloscope, a

good source of control voltage (calibrated CV/GATE 5

octave keyboard) a good voltmeter (at least 4000

pts), a digital tuner (I am using a Korg CA tuner)

and/or a good frequency counter.

WAVESHAPE CONVERTER SETTING

V/OCT TRACKING

TUNING

|

||||||||

Waveshapes - vertical

scale : 2V/square,

0V on the middle horizontal line

|

|

|

References |

Understanding TEMPCO  Ian Fritz Sawtooth VCO  |

|

|

|

||

| Name : Mariano Pseudo : Dhar2kma Modular project : Location : Dallas, Texas, USA Website : |

Name : Czaba

ZVEKAN Modular project : Location : Basel, Switzerland Website : |

Name : Patrick

Pseudo : Baronrouge Modular project: JHC live lab Location Toulon, France Web site : http://myspace.com/patjhc |

||

|

|

|

||

| Name : Julien Modular project : Location : Website : |

Name : Pseudo : Sebo Modular project : Location : Argentina Website : http://www.cosaquitosenglobo.com.ar |

Name : Julien Modular project : Location : Website : |

||

|

|

|

||

| Name : Zarko Modular project : Location : Gardanne, France Website : |

Name : Pseudo : Tudy Modular project : Yusynth 17U Location : Brno, Czech Republic Website :www.insania.freemusic.cz |

Name : Balazs Varga Pseudo : vinnui Modular project : Overmind modular Location : Hungary Website : http://vinnui.blogspot.com/ |

||

|

|

|||

| Name : Jim Coun Modular project : Location : Belgium Website : |

Name : Peter Hostermann Modular project : Location : Germany Website : http://www.peter-hostermann.de |

|

|||

|

|