reference

|

value

|

number

|

U5,

U102,

U202,

U302,

U402

|

TL072

|

5

|

U101,

U201,

U301,

U401 |

TL074

|

4

|

U103,

U203,

U303,

U403 |

LM13700 or

NJM13700

|

4

|

Q101,Q102,

Q201,Q202,

Q301,Q302,

Q401,Q402

|

BC557B (final B

is important !)

|

8

|

R1,R2

|

10

|

2

|

R125,R126,R133,R134,

R225,R226,R233,R234,

R325,R326,R333,R334,

R425,R426,R433,R434

|

100

|

16

|

R109,R121,

R209,R221,

R309,R321,

R409,R421

|

2.2K

|

8

|

R108,R120,R124,R129,R132,R137,

R208,R220,R224,R229,R232,R237,

R308,R320,R324,R329,R332,R337,

R408,R420,R424,R429,R432,R437

|

10K

|

24

|

R127,R135,

R227,R235,

R327,R335,

R427,R435

|

15K

|

8

|

| R3,R4 |

27K for +15V/-15V PSU, 12K for

+12V/-12V PSU

|

2

|

R122,R123,

R222,R223,

R322,R323,

R422,R423,

|

27K

|

8

|

R128,R136,

R228,R236,

R328,R336,

R428,R436

|

33K

|

8

|

R5,R6

|

47K

|

2

|

R104,R130,R138,

R204,R230,R238,

R304,R330,R338,

R404,R430,R438

|

100K

|

12

|

R105,R106,

R205,R206,

R305,R306,

R405,R406

|

150K

|

8

|

R102,R103,

R202,R203,

R302,R303,

R402,R403

|

200K

|

8

|

R101,

R201,

R301,

R401

|

330K

|

4

|

R131,

R231,

R331,

R431 |

1M

|

4

|

T101

T201

T301

T401 |

50K 1 turn

mini-trimmer

|

8

|

P101,P102,

P201,P202,

P301,P302,

P401,P402

|

100K LIN pannel

potentiometer

|

8

|

P103,

P203,

P303,

P403

|

200K or 220K or

250K LOG pannel potentiometer |

4

|

C104,C105,

C204,C205,

C304,C307,

C404,C407

|

100n ceramic

multilayer

|

8

|

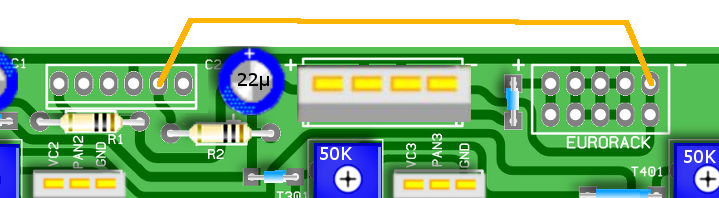

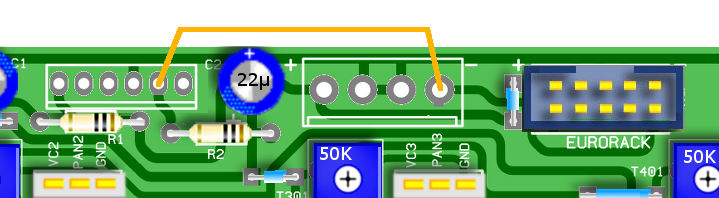

C1,C2

|

22µF/35V

polarized

|

2

|

C102,C103,

C202,C203,

C302,C303,

C402,C403

|

47µF/50V

polarized

|

8

|

C101,

C201,

C301,

C401

|

47µF/50V

non-polarized

|

4

|

Jk101,Jk102,

Jk201,Jk202,

Jk301,Jk302,

Jk401,Jk402

|

6,5 mm jack

socket

|

8

|

|

OUTPUT &

MONITOR STAGE

All resistors are

1% (1/4W to 0.6W) unless specified otherwise

reference

|

value

|

number

|

U3

|

TL072

|

1

|

U1,U2

|

TL074

|

2

|

Q1,Q2

|

BC327

|

2

|

Q3,Q7

|

BC337

|

2

|

D1,D2,D3,D4,D5,D6,D7,D8

|

1N4148

|

8

|

R1,R2

|

10

|

2

|

R35,R40

|

82 1/2W

|

2

|

R33,R34,R38,R3ç

|

150 1/2W

|

4

|

R16,R30

|

1K

|

2

|

R7,R21

|

3.3K

|

2

|

R12,R13,R26,R27

|

4.7K

|

4

|

R5,R6,R8,R19,R20,R22

|

10K

|

6

|

R15,R16,R20,R21,R26,R31

|

22K

|

6

|

R11,R25

|

68K

|

2

|

R3,R4,R14,R15,R17,R18,R28,R29

|

120K

|

8

|

R9,R23

|

220K

|

2

|

C3,C6,C13,C16

|

3.3n

|

4

|

| C4,C5,C14,C15 |

33n

|

4

|

C8,C18

|

220n

|

2

|

C13,C23

|

10µF/35V

|

2

|

C1,C2

|

22µF/50V

|

2 |

C7,C17

|

22µF/50V

non-polarized (preferred but not critical)

|

2

|

P13a,b

|

10K to 50K log

(audio) dual gang

|

1

|

P14a,b;P15a,b

|

100K linear dual

gang

|

2

|

P16a,b

|

100K log (audio)

dual gang

|

1

|

T1,T2

|

10K 1 turn mini

trimmer

|

2

|

V1,V2

|

MONACOR

V-22,Panel meter, 55x48 mm, with VU

lettering, 250µA/750Ω, ±10%, ref. number:

29.1050

|

2

|

Jk1,Jk2

|

6,5 mm jack

socket

|

2

|

Jk3

|

6,5 mm stereo

jack socket |

1

|

|